Vertical Split Case Centrifugal Pump Maintenance in Jeddah, Saudi Arabia

Regarding pump maintenance in Jeddah, Saudi Arabia, Vertical Split Case Centrifugal Pumps are crucial to various industries. Whether it’s water supply, drainage systems, or fire protection systems, these pumps do a lot of heavy lifting. But like any other mechanical equipment, proper maintenance ensures they function smoothly and reliably. So, if you’re responsible for keeping one of these pumps in top shape, you’re in for an informative yet crucial read.

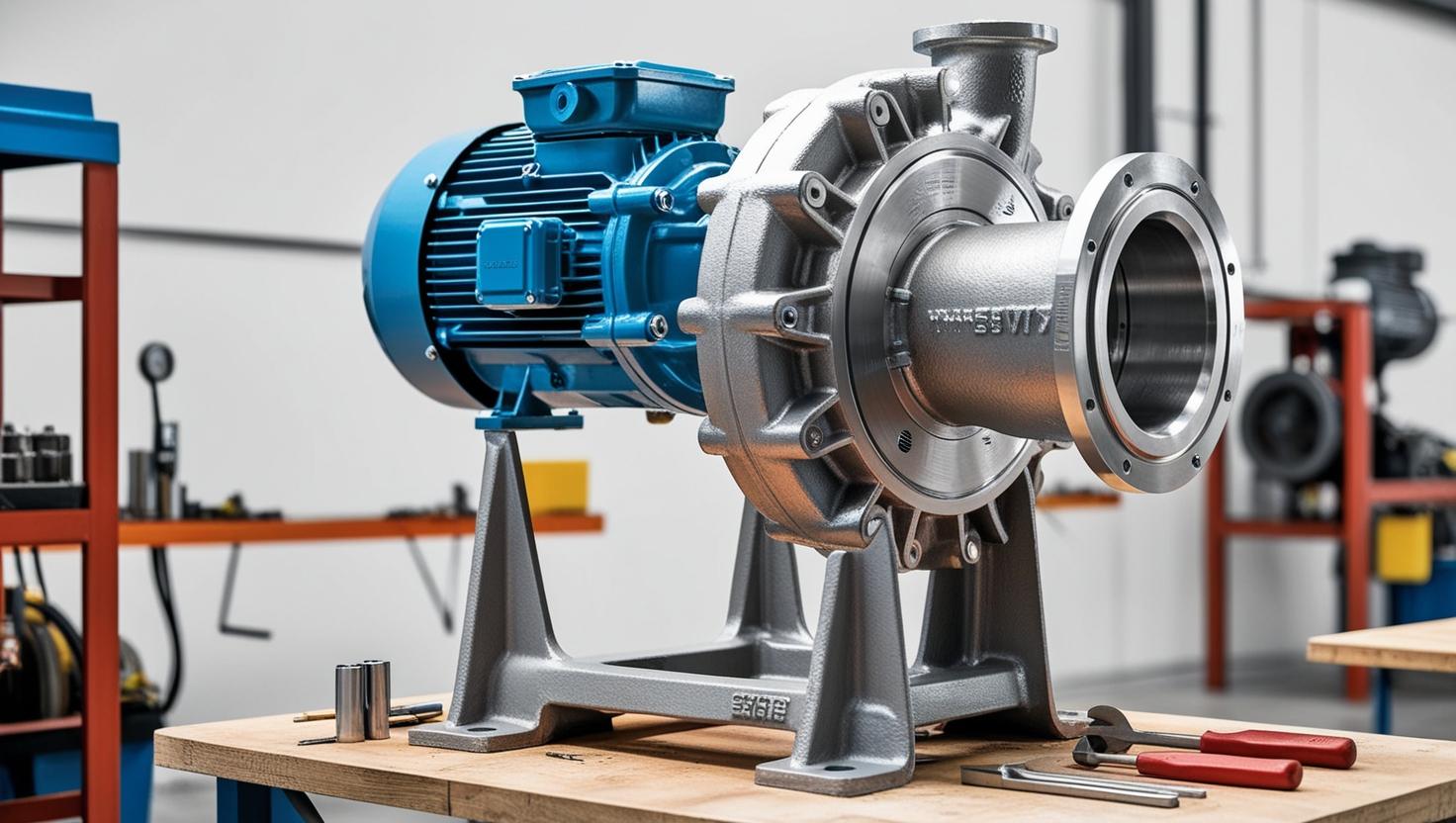

Introduction to Vertical Split Case Centrifugal Pumps

Vertical Split Case Centrifugal Pumps are typically used in high-flow applications. They are known for their efficient and reliable performance, especially when it comes to handling large volumes of water. These pumps are designed with a split casing, allowing easy maintenance and quick access to the internal components. This makes it easier to inspect, clean, and repair. These pumps can serve you for years with the correct pump service and maintenance practices.

In Saudi Arabia, especially in Jeddah, where industries rely heavily on water and fluid management systems, having a functional Vertical Split Case Centrifugal Pump is essential. However, all equipment requires regular maintenance and troubleshooting to ensure long-term operation. Let’s dive into how you can maintain these pumps properly, so they never let you down when you need them the most.

Step-by-Step Guide to Vertical Split Case Pump Maintenance

1. Routine Inspection and Monitoring

When it comes to pump maintenance, the first step is to monitor and inspect the equipment regularly. You need to check the pump’s performance consistently. If you’re noticing vibrations, abnormal noises, or changes in the pressure, these are clear indicators that the pump may need attention. This is why performing a visual inspection is essential. Check for leaks or any signs of wear in the seals and gaskets.

Regular monitoring for Vertical Split Case Pumps will help you spot potential problems before they escalate into significant failures. After all, a stitch in time saves nine, right? You don’t want to deal with expensive repairs or replacements later because you skipped the simple checks.

2. Lubrication of Bearings and Shaft

One of the most common maintenance tasks for a Vertical Split Case Centrifugal Pump is ensuring that the bearings and shaft are adequately lubricated. If lubrication is neglected, it can lead to excessive wear and tear, causing the bearings to seize up or the shaft to malfunction. Make sure to use the correct type of lubricants recommended by the manufacturer. Regular lubrication ensures that the pump’s moving parts operate smoothly, reducing the chances of costly breakdowns.

In Jeddah, where the climate can get quite hot, maintaining the lubrication of bearings is even more critical. The heat can cause lubricants to break down faster, so inspecting and reapplying lubricants frequently is essential. If you’re unsure, don’t hesitate to call in a pump repair service to ensure everything is in tip-top shape.

3. Cleaning the Impeller

The impeller of your Vertical Split Case Pump is the heart of the pump, responsible for transferring energy to the fluid being pumped. Over time, debris and sediment can accumulate around the impeller, leading to reduced performance or blockage. It’s essential to regularly clean the impeller, especially in environments like Jeddah, where dust and debris can enter the system. If you skip this step, you might notice a significant drop in pump efficiency or even complete failure.

Cleaning the impeller is a simple process, but it’s best done by someone experienced. If you’re unsure how to proceed, contact a vertical split case pump Grundfos service center for expert help.

4. Checking for Seal and Shaft Wear

Seals in a Vertical Split Case Pump prevent leaks and ensure the pump operates efficiently. Over time, these seals can wear down due to pressure or thermal expansion. It’s crucial to check the seals and shaft regularly to ensure that no leaks are present. If any cracks or signs of wear appear, it’s time to replace them.

In Jeddah’s demanding environment, where the pumps are used frequently, you want to ensure that all seals are intact. A minor leak can lead to a more significant problem if not addressed. Replacing a worn-out seal is far cheaper than dealing with the consequences of a complete pump failure.

5. Inspecting and Cleaning the Pump Bowl

Another often-overlooked part of pump maintenance is the pump bowl, where the fluid is pumped from the suction to the discharge. Over time, debris and scale can accumulate in the bowl, causing a decrease in pump efficiency. If this happens, the pump has to work harder, which puts unnecessary strain on the motor and increases energy costs.

To avoid this, it’s essential to clean the pump bowl regularly. Depending on the environment and how much dirt or sediment is in the pumped water, this cleaning can be done monthly or quarterly. If you’re in Jeddah, where industrial activity is often high, cleaning may need to be more frequent.

6. Motor and Electrical System Checks

A Vertical Split Case Centrifugal Pump is only as good as its motor and electrical system. Regularly checking the motor and its electrical components should be part of your pump service routine. Ensure that all wiring and electrical connections are secure, and there is no visible damage to cables or insulation.

In addition to the electrical connections, checking the motor for overheating or unusual noise is important. Overheating is a common issue that can damage the motor, resulting in expensive repairs. Having a professional technician handle motor maintenance is always a good idea to prevent complications.

7. Troubleshooting Pump Performance Issues

No matter how well you maintain your Vertical Split Case Pump, issues may still arise. The key is to identify these issues early and troubleshoot them. If you notice a sudden drop in performance or efficiency, it could be due to issues like cavitation, airlocks, or internal wear. Troubleshooting these problems requires some technical know-how, so don’t hesitate to consult an expert in Maintenance and Troubleshooting if you’re unsure.

In Jeddah, where pumps are subjected to extreme conditions, everyday performance issues include clogging and overheating. Keeping a regular schedule for troubleshooting ensures that you catch problems early and avoid costly downtime.

8. Replacement and Refurbishment

Sometimes, no matter how well you maintain your Vertical Split Case Centrifugal Pump, components will wear out and need replacement. In these cases, replacement is the best option. If you’re in Jeddah and need a pump repair or a replacement, look for a service provider specializing in vertical split case pump Grundfos models. They’ll have the right parts and expertise to get your pump up and running again.

In some cases, you might also consider refurbishment rather than replacement. Refurbishing a pump can be a cost-effective way to extend its lifespan, especially if the damage is not severe.

Conclusion

Maintaining a Vertical Split Case Centrifugal Pump in Jeddah, Saudi Arabia, is crucial for long-term performance. Following the steps outlined in this article, you can ensure that your pump runs smoothly, reduces the likelihood of unexpected breakdowns, and stays efficient throughout its lifecycle. Regular inspections, lubrication, cleaning, and troubleshooting are all part of a well-rounded maintenance plan.

Remember, don’t hesitate to call in the experts when in doubt. Pump repair services are available to help keep your systems in top shape, and at Pumpsservices.com, we specialize in just that. Contact us today at +966597747661 or email info@Pumpsservices.com for all your pump maintenance and service needs.

poneclub

Poneclub’s the place where I spend my fun time every night. A real community vibe. You guys gotta try it! Here’s the link: poneclub