High-Pressure Multistage Pumps Maintenance

High-pressure multistage pumps are crucial in many industrial applications, including water supply systems, HVAC systems, and chemical processing. These pumps are designed to handle high pressures while maintaining efficiency over a long service life. However, like all machinery, they require proper maintenance to ensure optimal performance. This article will discuss high-pressure multistage pump maintenance in a straightforward and easy-to-understand manner.

What Are High-Pressure Multistage Pumps?

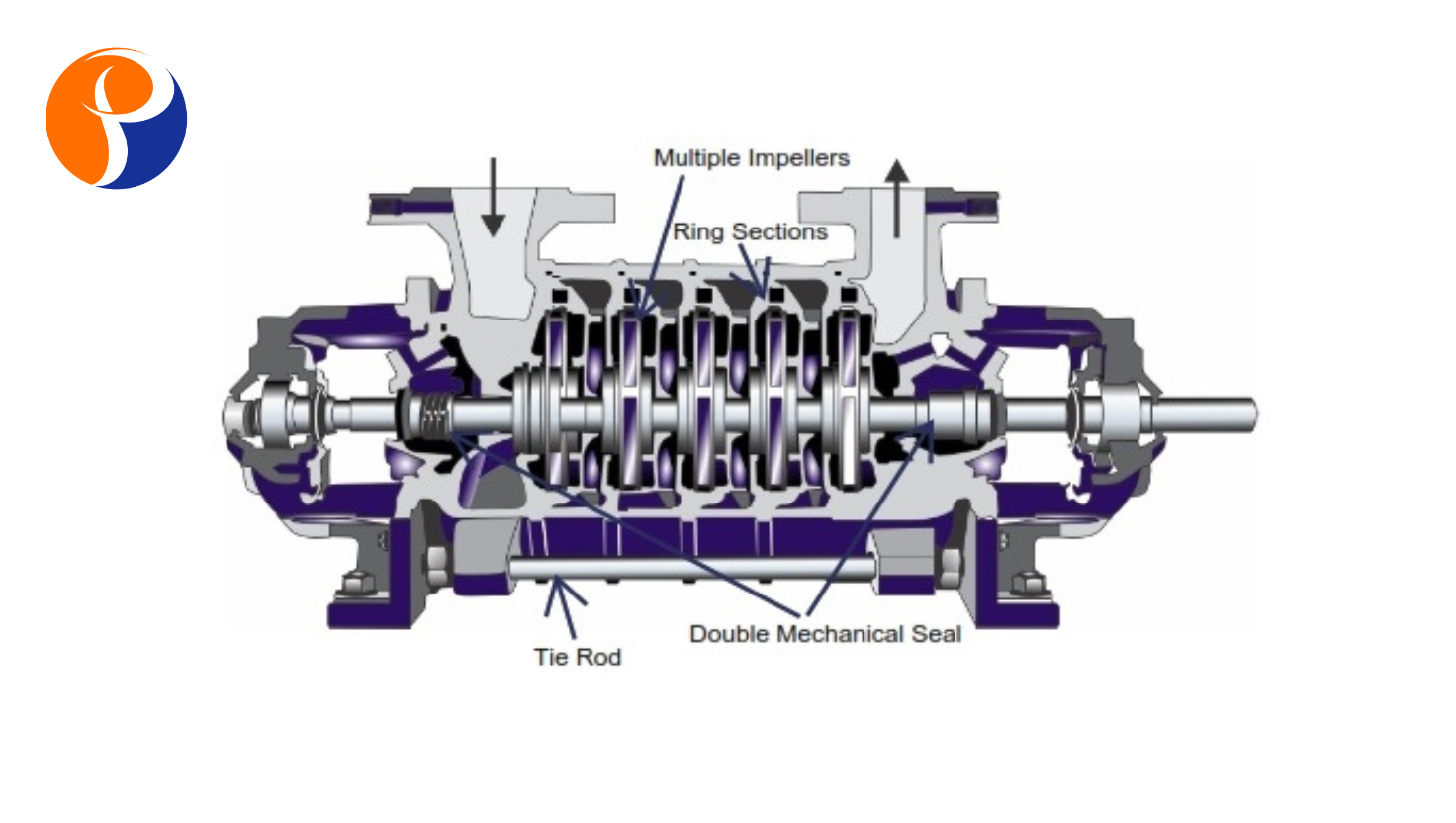

Before diving into maintenance, let’s understand a high-pressure multistage pump. High-pressure multistage pumps are designed to pump water or other fluids at high pressure levels. These pumps consist of multiple impellers arranged in stages, which help increase the fluid’s pressure as it moves through the pump. Each impeller adds more pressure to the fluid, making these pumps ideal for applications that require high pressure, such as boiler feedwater systems, water treatment plants, and even irrigation systems in large agricultural setups.

Since these pumps work under high pressure, they face a lot of strain during operation. Hence, regular pump maintenance is essential to prevent premature wear, efficiency loss, and sudden breakdowns.

Why Is High-Pressure Multistage Pump Maintenance Important?

Maintaining high-pressure multistage pumps is not only about ensuring longevity but also improving their efficiency and avoiding costly repairs. When adequately maintained, these pumps can work at peak efficiency, saving energy costs and minimizing downtime.

Pump maintenance involves several tasks, from cleaning and lubrication to more complex actions like checking the mechanical seals or performing performance tests. Regular maintenance can extend the pump’s life and keep it running smoothly. If maintenance is neglected, you might encounter issues like cavitation, excessive vibration, or even pump failure—situations no one wants to deal with.

By staying proactive with maintenance, you prevent unexpected repairs and ensure that your KSB high-pressure multistage pumps work efficiently over the long term.

Step-by-Step Guide for High-Pressure Multistage Pumps Maintenance

Let’s walk through a simple step-by-step process for maintaining your high-pressure multistage pumps.

1. Regular Inspection of Components

Inspecting the different components of your pump is the first step in maintenance. Start by checking the mechanical seals and bearings. These parts are often under heavy load and can wear out quickly if not monitored. It might be time for a replacement if they show signs of damage.

Next, inspect the pump casing and impellers. Over time, these parts can develop cracks or corrosion, primarily if the pump handles harsh chemicals or abrasive fluids. Ensure the casing is intact for KSB pumps in Jeddah or any other location to prevent leakage.

2. Lubrication and Cleaning

One of the most essential parts of pump service is ensuring that all moving parts are adequately lubricated. Lack of lubrication can cause friction, which leads to heat generation and accelerated wear. Use the correct type of lubrication as recommended by the manufacturer.

Cleaning is also critical. Debris, dirt, or sediment can build up inside the pump and clog the internal components. This can reduce efficiency and lead to performance issues. Pump repair might be necessary if debris accumulates, as this can damage sensitive parts like seals and bearings.

3. Check for Leaks and Vibration

Leaks clearly indicate something is wrong with your high-pressure multistage pump maintenance. Leaks can often be traced to worn seals, cracked pipes, or loose fittings. Identifying and fixing leaks early can prevent water damage and reduce the risk of system failure.

Excessive vibration is another common issue with pumps under high pressure. While some vibration is normal, it can lead to mechanical failure if it becomes pronounced. Check for any misalignment in the shaft or other moving parts. Adjustments may be needed to reduce vibrations and avoid damage.

4. Performance Testing

Every few months, perform a performance test on your pump. This involves measuring the output pressure and flow rate and comparing them to the manufacturer’s specifications. If the readings are off, there could be an issue with the impellers or the pump’s internal components.

A drop in performance might indicate internal wear or clogging, and it’s often a sign that pump service is needed. Regular performance testing ensures that you catch issues before they cause significant damage.

5. Monitor Pressure and Temperature

High-pressure pumps generate a lot of heat during operation. Ensure that the temperature is kept within the recommended range. If the pump runs too hot, it could lead to thermal expansion, which can cause seals and gaskets to break down prematurely.

Pressure levels should also be regularly monitored. Excess pressure can stress the pump’s internal components, leading to early failure. Pump maintenance services often involve checking and adjusting pressure settings to prevent these issues.

Signs You Need Professional Pump Repair

While routine maintenance is essential, there are times when you need to call in a professional for KSB pump repair or general high-pressure multistage pump repair. Here are a few signs that you should seek professional help:

-

Decreased performance: If the pump isn’t producing the expected flow or pressure, it might be time for a professional check-up.

-

Strange noises: If you hear grinding, squealing, or knocking noises, it could indicate problems with the bearings or shaft alignment.

-

Frequent overheating: Overheating could indicate issues with lubrication or excessive friction within the pump components.

Professional pump service providers, like Pumpsservices.com, are equipped to handle these problems efficiently. Contact them at info@Pumpsservices.com or call +966597747661 for expert advice and repairs.

Conclusion

Regular high-pressure multistage pump maintenance is crucial to ensuring the reliability and longevity of your equipment. Following a maintenance routine that includes inspections, lubrication, cleaning, and performance testing can prevent costly repairs and keep your pump running at peak performance. If you ever notice issues with your pump, don’t hesitate to reach out for professional KSB pump repair or service.

Remember, your pump is an investment. Keeping it in top shape means fewer headaches down the road. Stay proactive, and your high-pressure multistage pumps will continue to serve you for many years.

For more information about pump maintenance and services, visit Pumpsservices.com, or contact us at info@Pumpsservices.com or +966 55 278 1957.

wjpesoph

Wjpeosph, is funny on there. It offers many type of game. Gameplay is smooth, and the site’s well-optimized. This wjpesoph