Split-Case Centrifugal Pump Maintenance

Welcome to the world of Split-Case Centrifugal Pump Maintenance! If you’re reading this, you probably have one of these industrial workhorses humming away in your plant. Think of this pump as the reliable, if slightly demanding, friend who gets the job done but needs a little TLC to avoid a major meltdown. Neglecting it is like ignoring a strange noise in your car—it might be fine for a while, but eventually, you’re in for a big, expensive surprise.

This guide will walk you through the essentials of keeping your pump in top shape. We’ll cover everything from a simple daily glance to the more involved process of a teardown inspection. The goal is simple: prevent downtime, save money, and keep the fluids flowing. Whether you’re dealing with a common horizontal split case pump or a space-saving vertical split case pump, the core principles of care are very similar. For expert help, remember you can always contact us at +966597747661 or info@pumpsservices.com.

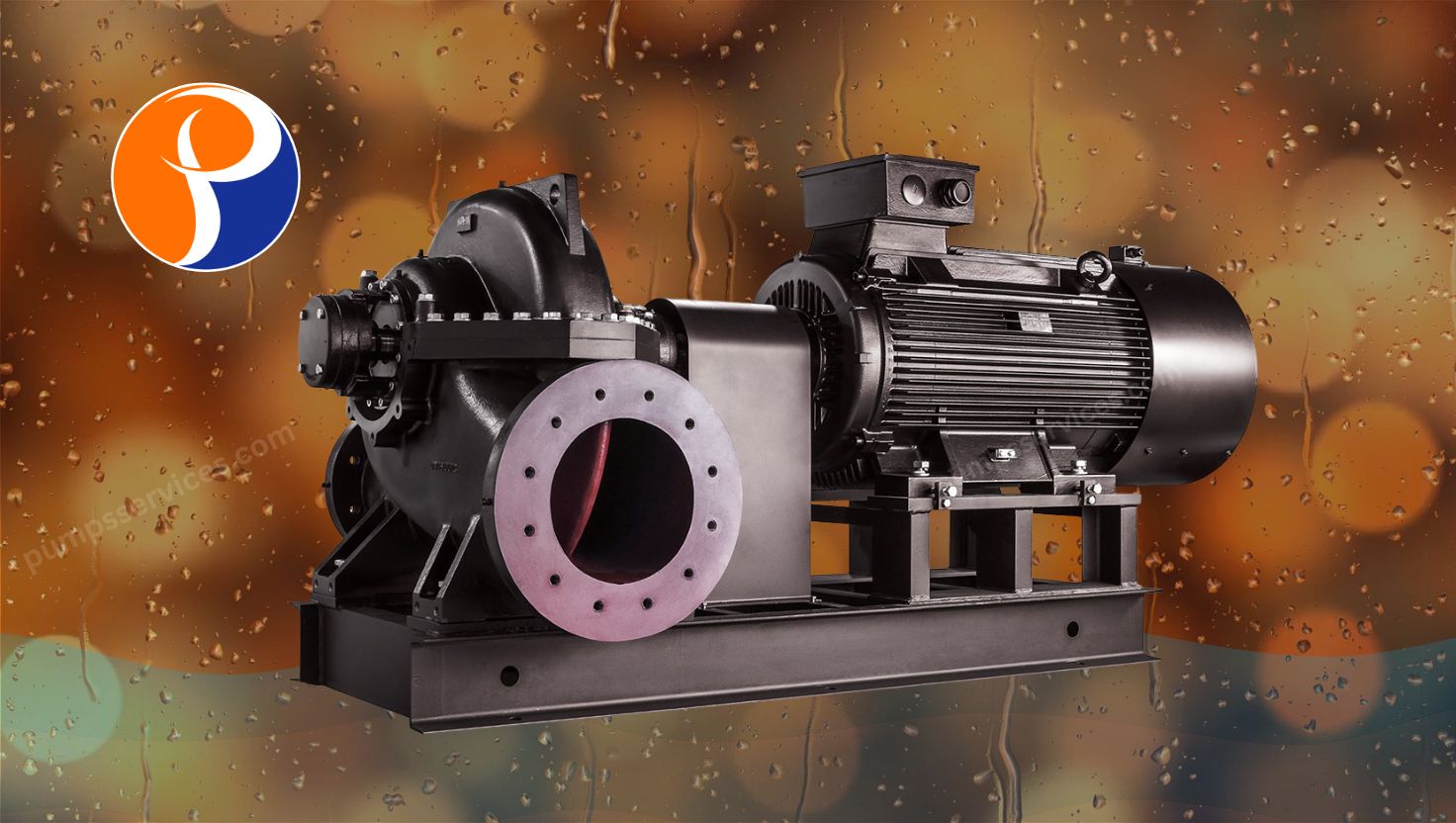

What is a Split-Case Centrifugal Pump Anyway?

Before we dive into maintenance, let’s quickly understand what we’re dealing with. A Split-Case Centrifugal Pump is designed with its casing literally split into two halves—horizontally or vertically. This brilliant design means you can access the entire rotating assembly (impeller, shaft, bearings) without disturbing the piping connected to the casing. It’s like being able to fix a car engine by just lifting the hood, instead of having to remove the entire engine from the car. This makes pump maintenance significantly easier.

There are two main types. The horizontal split case pump is the most common, with the shaft positioned horizontally. Its cousin, the vertical split case pump (like the popular vertical split case pump Grundfos models), has a vertical shaft, which saves a lot of floor space. While they look slightly different outside, their internal maintenance needs are those of brothers from another mother. Proper care for a vertical split case centrifugal pump maintenance routine follows the same critical steps as its horizontal counterpart.

The Daily and Weekly Check-Up: An Ounce of Prevention

You don’t need a master mechanic to perform these basic checks. A few minutes each day can save you days of headache later. The key is to use your senses: look, listen, and feel. First, look for any signs of leaks, especially around the mechanical seal or gland packing. A small drip might seem harmless, but it’s a sign that something is wearing out. Second, listen for unusual noises. A happy pump has a steady hum. Grinding, screeching, or knocking sounds are its way of crying for help.

Next, feel the pump (be careful of hot surfaces!). Feel the bearings for excessive heat. If it’s too hot to touch, there’s a problem with lubrication or alignment. Also, check for unusual vibrations. A smooth operator will have minimal vibration; a shaky one tells you something is out of balance. This simple sensory inspection is the pump maintenance program’s first and most important part. It’s the equivalent of checking your car’s oil and tire pressure.

The Quarterly Deep Dive: Getting Your Hands Dirty

It’s time for a more thorough inspection every three to six months (depending on how hard the pump works). This is where we move from passive observation to active Split-Case Centrifugal Pump Maintenance. The star of this show is often Laser Alignment Services. If the pump and motor are misaligned, even by a hair, it causes premature wear on bearings, seals, and the coupling itself. Think of it as trying to ride a bicycle with a bent wheel—you’ll get there, but it’s a rough ride that wears everything out quickly.

After ensuring perfect alignment, this is a good time to check the bearing lubrication. Drain the old oil or grease and replace it with the manufacturer-recommended type. Over-greasing can be as bad as under-greasing, so follow the specs! Also, inspect the coupling for signs of wear or cracking. For a horizontal split case pump, this is relatively straightforward. You might need to check the external bracket bearings for a vertical split case pump. This proactive approach is the keyword for extended pump life.

The Annual Teardown: The Major Service

Once a year, or after about 8,000 hours of operation, your Split-Case Centrifugal Pump deserves a spa day. This involves shutting it down, isolating it from the system, and carefully disassembling it. The goal is to inspect, clean, and replace worn parts before they fail. This is the core of preventative pump maintenance and is non-negotiable for critical applications.

Here’s a step-by-step outline of the process:

-

Safety First: Lock out and tag out the power source. Ensure the pump is completely depressurized and drained.

-

Disassembly: Carefully separate the two halves of the casing. This will expose the impeller and shaft.

-

Inspection and Cleaning: This is the critical part.

-

Inspect the Impeller: Look for erosion, corrosion, or cavitation damage. Even minor imperfections can hurt performance.

-

Check the Wear Rings: These protect the casing and impeller. If the clearance is beyond the manufacturer’s limit, replace them.

-

Examine the Shaft and Seals: Check the shaft for scoring or wear where the seal rides. Replace the mechanical seal or packing as a matter of course during this annual service.

-

-

Reassembly: Carefully put everything back together with new gaskets. This is another perfect time for Laser Alignment Services to ensure everything goes back together perfectly.

When to Call the Professionals at pumpservices.com

There’s no shame in calling for backup. If you discover major issues like a severely damaged impeller or a bent shaft or simply don’t have the tools or time, Specialized tasks, especially precision Laser Alignment Services, are often best left to professionals to ensure they’re done right the first time.

At pumpservices.com, we live and breathe pumps. Our team has the experience and equipment to handle everything from a routine service to a significant overhaul for any pump, whether a robust horizontal split case or a complex vertical split case Grundfos unit. Don’t let a minor problem become a catastrophic failure. A little planned pump maintenance is always cheaper than an unplanned breakdown. Remember, a well-maintained pump is a happy pump, which means a happy you!

cannabis mystery box

weed delivery global safe worldwide

Split Case Centrifugal Pump Maintenance

[…] Pump Maintenance: A No-Sweat Guide to Keeping Things Flowing. Let’s be honest: the term Split Case Centrifugal Pump Maintenance might not make your heart race with excitement. For many, it sounds like a complicated, oily chore […]

jilifishslot

Jilifishslot is my go-to when I’m lookin’ for a quick slots fix. The fish games are super addictive, and they’re a great way to unwind after a long day. Give it a try, you might find yourself hooked! Check out jilifishslot and catch some wins.