PUMP LASER ALIGNMENT Precision Services by Pumps Services: Your Guide to a Happy, Healthy Pump

PUMP LASER ALIGNMENT. Let’s be honest. When you think about the most exciting part of your industrial or facility operations, pump and motor alignment probably ranks somewhere between watching paint dry and reading the phone book (remember those?). Most folks see a pump humming away and think, “Great, it’s working!” and move on. However, what you don’t see is the silent, slow-motion disaster happening inside if that pump and its motor are even slightly out of whack. It’s like driving a car with the wheels misaligned—sure, it moves, but you’re burning through tires and fuel at a ridiculous rate.

That’s where PUMP LASER ALIGNMENT Precision Services by Pumps Services comes in. Think of us as the expert optometrists for your machinery. We don’t just give your equipment a quick glance; we perform a full vision exam with the fanciest, most precise tools to make sure everything is perfectly in line. This isn’t just a minor tweak; it’s a critical service that saves you a mountain of cash, prevents headaches, and keeps everything running smoothly. So, grab a coffee, and let’s dive into the surprisingly important world of getting two spinning things to play nicely together. For all your alignment needs, visit us at pumpsservices.com or simply call +966564709249.

Why Bother With Pump Alignment Anyway?

Imagine trying to clap with your hands constantly at slightly wrong angles. It would be tiring, your hands would get sore, and you’d look pretty silly. Now, imagine your pump’s Shaft and the motor’s Shaft are those hands. When they are misaligned, even by tiny amounts measured in thousandths of an inch (or mils), they are fighting each other. This fight leads to vibration, excessive heat, and severe wear on seals, bearings, and the shafts themselves. Before you know it, you’re facing a catastrophic failure right in the middle of a crucial process. Not fun.

Therefore, implementing a proper pump alignment procedure is not maintenance—it’s an investment in peace of mind. Proper alignment extends the life of your components by years, slashes your energy consumption (a happy pump is an efficient pump), and eliminates unplanned downtime. It’s one of the highest-return activities you can do in your plant. Whether you’re looking for reliable pump alignment services in Jeddah or elsewhere, understanding this “why” is the first step toward smarter operations.

The Old Way vs. The New Light: Dial Indicator vs. Laser

For decades, the trusty tool for pump and motor alignment was the dial indicator. This method. The pump alignment procedure with a dial indicator is a skill honed by seasoned mechanics. It involves mounting gauges on the shafts and manually rotating them to measure misalignment. It’s accurate in skilled hands, but let’s be real—it’s slow, requires a lot of math and interpretation, and is highly dependent on the person’s experience. It’s like navigating with a paper map versus a GPS.

Enter the superhero of our story: the pump laser alignment tool. This technology has revolutionized the field. Basically, you attach a laser transmitter to one Shaft and a receiver to the other. As you rotate the shafts, the laser beam traces their positions, and a computer calculates the exact misalignment to micron-level precision. It’s faster, incredibly accurate, and gives clear, visual instructions on exactly which shim to add or which bolt to turn. This is the core of modern Laser Shaft Alignment services. Want a pump laser alignment review from satisfied customers? The consensus is clear: once you go laser, you never go back.

A Buffet of Misalignment: Understanding Pump Alignment Types

Misalignment isn’t a one-trick pony; it comes in different flavors, and sometimes, you get a mixed bowl. Knowing the pump alignment types helps diagnose the issue. First, you have angular misalignment. This is where the shafts are at an angle to each other, like two leaning towers. They might meet at the coupling, but they’re not parallel. Next is parallel misalignment (or offset misalignment). Here, the shafts are parallel, but their centerlines are offset—they’re like two train tracks that are supposed to be joined but are slightly side-by-side.

In the messy real world, you almost always have a combination of both, aptly named compound misalignment. A proper Laser Alignment procedure identifies and corrects all these types simultaneously. Furthermore, there’s a sneaky culprit called soft foot, which isn’t a misalignment of the shafts but of the motor itself. If the motor base isn’t flat on its foundation, tightening the bolts will twist the motor frame, creating a false alignment reading. Any good Shaft alignment services near me will always check and correct soft foot first—it’s Alignment 101.

Hitting the Bullseye: What Are Pump Alignment Acceptable Values?

This is the million-dollar question: “How good is good enough?” You can’t just eyeball it and say, “That looks straight.” Precision is key. The acceptable pump alignment values are typically defined by the equipment manufacturer and the machine’s rotational speed. Generally, the faster a machine spins, the more precise the alignment needs to be. Tolerances are usually given in mils (thousandths of an inch) or microns.

For instance, a common standard for many industrial pumps is to be within 0.002 inches (2 mils) for offset and 0.001 inches per inch of coupling gap for angularity. But here’s the kicker: these are just acceptable values. For truly optimal, energy-efficient, and long-lasting operation, aim for the best possible values, often far tighter than the standard. This pursuit of perfection is what defines PUMP LASER ALIGNMENT Precision Services by Pumps Services. We don’t aim for “okay”; we aim for “optimal,” ensuring your machinery runs like a dream.

Gearing Up: An Overview of Pump Alignment Tools

You can’t build a house without a hammer, and you can’t align a pump without the right instruments. The category of pump alignment tools ranges from the simple to the sophisticated. At the basic end, you have straight edges and feeler gauges—fine for a very rough, preliminary check, but about as useful as a sundial for running a railway. Then, as discussed, you have the mechanical pump alignment procedure with dial indicator kits, which include brackets, dial gauges, and stands.

At the pinnacle are the digital laser Shaft alignment systems. These modern pump laser alignment tool kits include the laser/detector units, a handheld computer or tablet, chain or magnetic mounts, and, often, accessories for measuring soft foot and machine movement. They are the Formula 1 cars of the alignment world. Investing in the right tools, or hiring a service that uses them, is non-negotiable for serious maintenance. In fact, using a top-tier Laser Alignment Services provider with advanced tools is often more cost-effective than buying and learning the system yourself for occasional use.

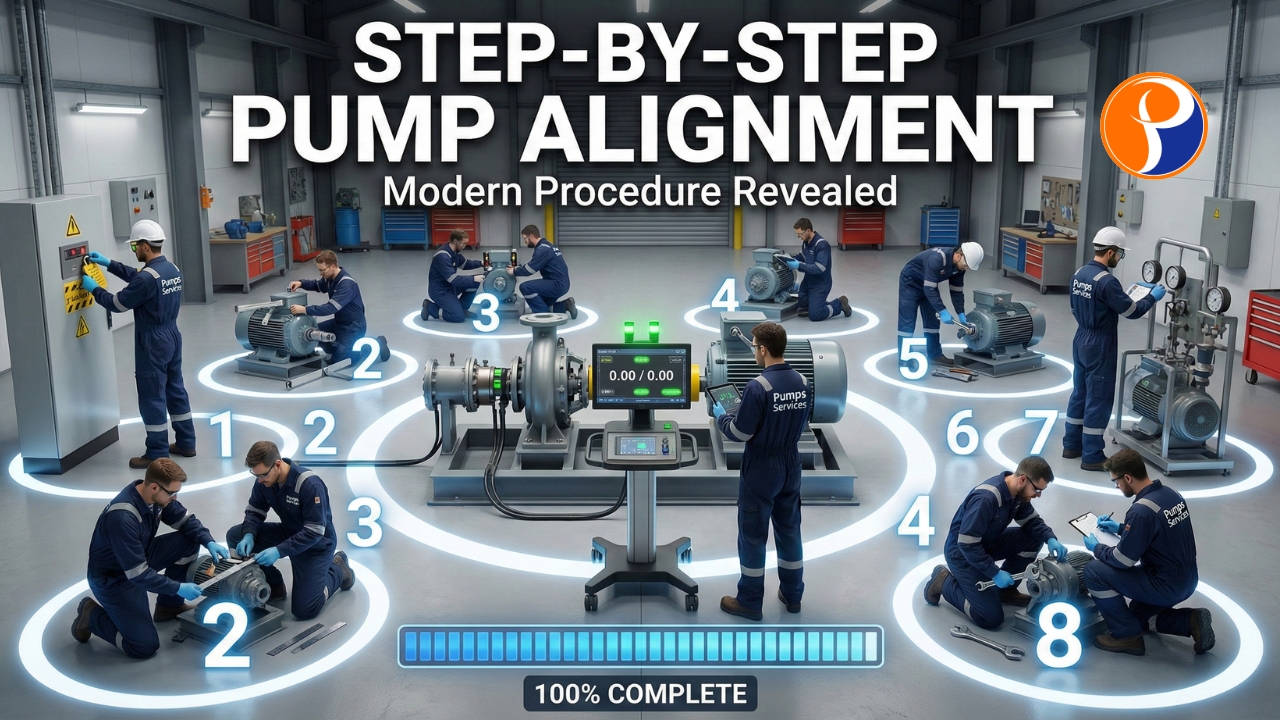

Step-by-Step: The Modern Pump Alignment Procedure

So, what does a technician actually do during a Laser Alignment | Shaft Alignment service? Let’s walk through a simplified version of the modern pump alignment procedure. First, safety is paramount—the equipment must be locked out and tagged out (LOTO). No exceptions. Next, the technician performs a pre-alignment check. This includes inspecting the foundation, checking for loose hold-down bolts, and, crucially, measuring and correcting soft foot. You’d be amazed at how many problems are solved right here.

Then, the laser alignment tool is mounted onto the two shafts. The technician rotates the shafts together, and the system collects data, displaying a live picture of the misalignment. The software then provides clear, step-by-step instructions: “Add 0.10 mm shim under front foot” or “Move motor 0.05 mm to the south.” The technician makes the adjustments, takes new readings, and repeats until the alignment is within the desired, often very tight, tolerances. Finally, a full report is generated, documenting the “before” and “after” state—a health certificate for your pump.

The Cost of Precision: Pump Laser Alignment Price vs. The Price of Failure

“How much does this pump laser alignment price run?” It’s a fair question. The cost can vary based on the size and accessibility of the machine, your location (like for specialized pump alignment services in Jeddah), and the service provider’s expertise. You might pay a few hundred to a couple of thousand dollars for a professional service. Now, before you gasp, let’s put that in perspective.

Consider the alternative cost: a single failed bearing or seal can cost thousands in parts and labor. Unplanned downtime can cost tens of thousands per hour in lost production. A major Shaft or impeller failure? That’s a five-figure problem, easy. Compared to this, professional Laser Shaft Alignment is ridiculously cheap insurance. It’s the difference between a regular dental check-up and a full root canal. When you search “pump laser alignment near me,” you’re not just looking for a cost; you’re investing in reliability.

Finding Your Alignment Partner: Laser Alignment Services Near You

You’re convinced. You need this done. Now, how do you find a great service?. A quick search for “Laser Alignment Services” or “Shaft alignment services near me” will give you options, but not all are created equal. Look for a provider with proven experience, certified technicians, and testimonials. They should use modern, well-calibrated equipment and be willing to explain the process and results to you.

This is where we, at Pumps Services, shine. Our PUMP LASER ALIGNMENT Precision Services by Pumps Services is what we live and breathe. We combine cutting-edge. Laser Shaft alignment technology with deep practical knowledge to solve your real-world problems. We don’t just take a reading and leave; we ensure your system is set up for long-term success. Ready to stop burning money on vibration and wear? Contact the experts. Visit pumpsservices.com for more information or call us directly at +966564709249 to schedule a consultation. Let’s get your pumps running smoothly, efficiently, and without the drama.