Pump Testing and Commissioning

Pump Testing and Commissioning Pump Testing and Commissioning: No More Guessing Games! Alright, let’s talk about pumps. You’ve just installed a shiny new pump (or maybe you’re about to). It looks impressive, doesn’t it? But here’s the secret no one tells you: a pump sitting quietly in its place is like a race car parked in a garage. It might look the part, but you don’t know if it can perform. That’s where the superhero duo of the pumping world comes in: pump testing and commissioning. This isn’t just paperwork; it’s the grand opening ceremony for your pump, ensuring it’s ready for years of reliable service. Think of it as the pump’s final exam before it graduates to the big leagues.

This process is the heart of professional pump maintenance. Skipping it is like buying a fancy cake and not tasting it before the party—you’re just hoping for the best. Proper pump testing and commissioning is your guarantee that everything from the power supply to the last pipe connection is working in perfect harmony. It’s the difference between a system that hums along happily and one that groans, leaks, and gives you a headache every other week. For anyone searching for “pump maintenance near me“, understanding this process is the first step to knowing what quality service looks like.

What in the World is Pump Testing and Commissioning?

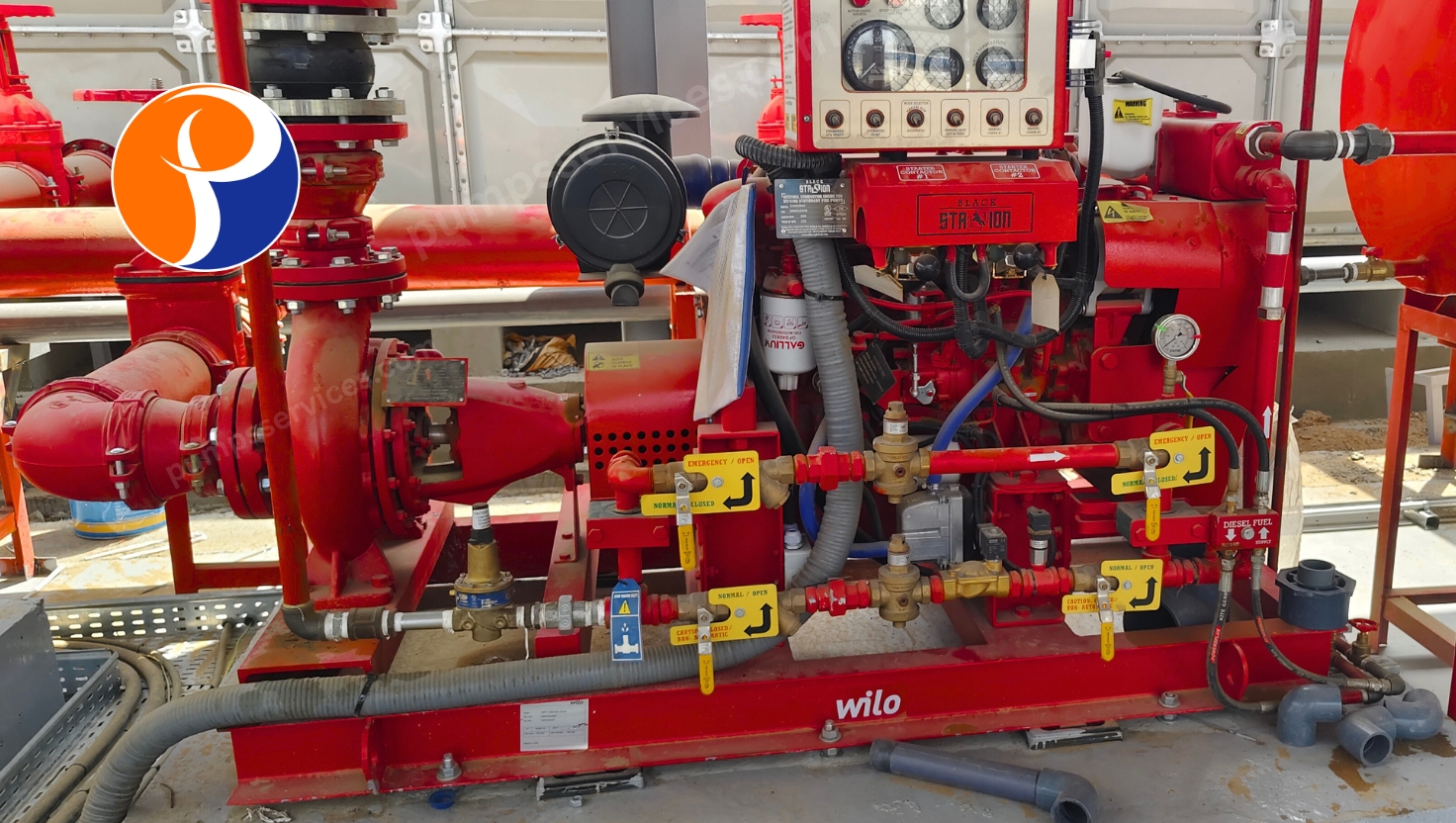

Let’s break down this technical-sounding phrase. Pump testing is the “show me” part of the process. It involves running the pump and collecting complex data—like pressure, flow rate, power consumption, and vibration levels. We compare this data against the pump’s design curves, which are basically its promise to you from the manufacturer. If the numbers match, you’re golden. If not, we’ve caught a problem early. This is critical to any thorough Water pump maintenance plan, ensuring the pump’s heart beats as it should.

On the other hand, commissioning is the “make it official” part. It’s the comprehensive process of documenting that the pump, and the entire system it’s part of, has been installed, tested, and is ready for operational duty. This includes checking valves, controls, safety alarms, and more. It’s the final seal of approval. So, while testing gives us the numbers, commissioning gives us confidence that the whole system is a cohesive, safe, and efficient unit.

The Step-by-Step Dance of Testing and Commissioning

The Pre-Startup Mingle (Pre-Commissioning Checks)

Before we even think about hitting the “on” button, we have to do the equivalent of checking our shoelaces before a run. This stage is all about visual and mechanical checks. Is the pump rotation correct? (Yes, pumps can spin the wrong way!). Are the bolts tight? Is there enough lubrication? Is the suction line free of blockages? We also ensure the electrical connections are secure and the voltage is correct. It’s a crucial step that prevents 90% of startup disasters.

Furthermore, we verify that all valves are in the correct position. The discharge valve, for instance, should be partially closed during startup to reduce the load on the motor—a little trick that keeps everything happy. This careful attention to detail separates a professional pump testing and commissioning service from a simple installation. The tedious but essential groundwork makes the exciting part go smoothly.

The Main Event: Performance Testing

This is where the action happens! We start the pump and let it run, but we’re not just watching it spin. We’re collecting key performance indicators. The most important ones are:

-

Flow Rate: How much water is the pump actually moving?

-

Pressure: Is the pump building up the required pressure?

-

Amperage Draw: Is the motor using the expected amount of electricity?

We run the pump at various operating points to see how it behaves under different conditions. This is especially critical for booster pump testing and commissioning, where consistent pressure is the goal. If the pressure is too low, your showers become a trickle; if it’s too high, you risk damaging your pipes. Getting this balance right is an art and a science.

The Final Bow: System Integration and Handover

Once we’re satisfied that the pump is a superstar, we must ensure it plays well with others. We tested the control panel. Do the start/stop buttons work? Do the safety alarms (for low pressure or high temperature) function correctly? We simulate fault conditions to see how the system responds. Finally, we let the system run sustainably to ensure stability. This is the final proof that your pump maintenance plan is off to a rock-solid start.

We provide a commissioning report after all tests are passed with flying colors. This document is the pump’s birth certificate and health record. It includes all the test data, settings, and as-built drawings. This report is invaluable for future troubleshooting or Water pump maintenance. It’s the final handshake, signaling that the pump is officially yours and ready for a long, productive life.

Why Bother? The Perks of Doing It Right

You might think, “This sounds like a lot of work.” And you’re right, it is! But it’s work that pays for itself many times over. Proper commissioning maximizes pump efficiency, which directly translates to lower energy bills. It extends the pump’s lifespan by ensuring it never operates under stressful conditions. Most importantly, it prevents catastrophic failures that can lead to downtime, flooding, or costly repairs.

For businesses, this is a no-brainer. For those looking for a great deal, some specialized providers, like us at PumpsServices.com, even offer free booster pump testing and commissioning with specific installations to ensure your peace of mind from day one. It’s our way of saying we stand behind our work.

Your Next Steps for a Happy Pump

Don’t leave your pump’s performance to chance. Whether dealing with a simple water pump or a complex multi-stage booster system, professional pump testing and commissioning is the key to unlocking its full potential. It turns a significant investment into a reliable workhorse.

If you have a new installation or an existing pump that’s never been properly commissioned, it’s never too late to get it done right. Don’t hesitate to contact us for expert service and advice. We’re here to ensure your pumps work for you, not the other way around!

Contact Us Today!

Phone: +966597747661

Email: info@pumpsservices.com

Website: PumpsServices.com

(FAQs)

You’ve read the guide, but you might still have some questions. That’s totally normal! This stuff can seem detailed. So, we’ve gathered and answered the most common questions in plain English. Think of this as a quick chat over coffee about all things pumps.

Is pump testing and commissioning essential? It seems expensive.

- This is the big one! Think of it this way: would you buy a new car and never check the oil, tire pressure, or brakes? Probably not. Pump testing and commissioning are the same essential check-up for a critical piece of your water system. The small, upfront cost of proper commissioning is nothing compared to the price of a significant breakdown, flooded basement, or sky-high electricity bill from an inefficient pump. It’s not an expense; it’s an investment in peace of mind and long-term savings. This is the core of smart pump maintenance.

How long does the entire process usually take?

- There’s no one-size-fits-all answer, as it depends on the pump’s size and complexity. For a standard residential water pump, it might take a few hours. For a large industrial system or a detailed booster pump testing and commissioning project, it could take a full day or more. The key is that we don’t rush it. We take the time needed to collect accurate data and ensure every component is perfect. We’ll always give you a clear timeframe before we start.

Can I do the testing and commissioning myself?

- We love a good DIY spirit! You can certainly do some basic checks, like looking for leaks or listening for strange noises. However, measuring flow, pressure, and electrical parameters requires specialized tools and training. More importantly, misinterpreting the data can lead you to believe a pump is fine when it’s actually straining itself to death. For a proper Water pump maintenance check and to validate the warranty, it’s always best to call a professional. A quick search for “pump maintenance near me” should connect you with a qualified expert.

What’s the deal with “Free booster pump testing and commissioning”?

- It’s exactly what it sounds like, and yes, it’s real! At PumpsServices.com, we sometimes offer Free booster pump testing and commissioning as part of a new installation package. Why? Because we’re so confident in our installations that we want to prove it to you with data. It’s our way of ensuring you get the maximum performance from day one and building a trusting relationship. It’s always best to ask your provider if this is included!

My pump has already been installed, but has never been commissioned. Is it too late?

- It’s never too late for a check-up! While it’s ideal to commission a pump right after installation, we can perform a complete performance analysis on an existing system. This is often called “benchmarking.” We can identify if your pump is running inefficiently, has a hidden issue, or is simply the wrong size for the job. This can be the first step in a new, effective pump maintenance strategy that saves you money and hassle.

What exactly is in the final commissioning report I receive?

- Good question! The report is your pump’s official diploma. It’s not just a piece of paper; it’s a valuable document that includes:

-

As-Found Data: All the pressure, flow, and amp readings we took.

-

Pump Curve Comparison: A graph showing your pump’s performance against the manufacturer’s promise.

-

Settings Documentation: The exact settings for all controls and safety shut-offs.

-

Recommendations: Any notes on future maintenance or observations.

This report is beneficial for troubleshooting future issues or subsequent Water pump maintenance.